Portada » WPs

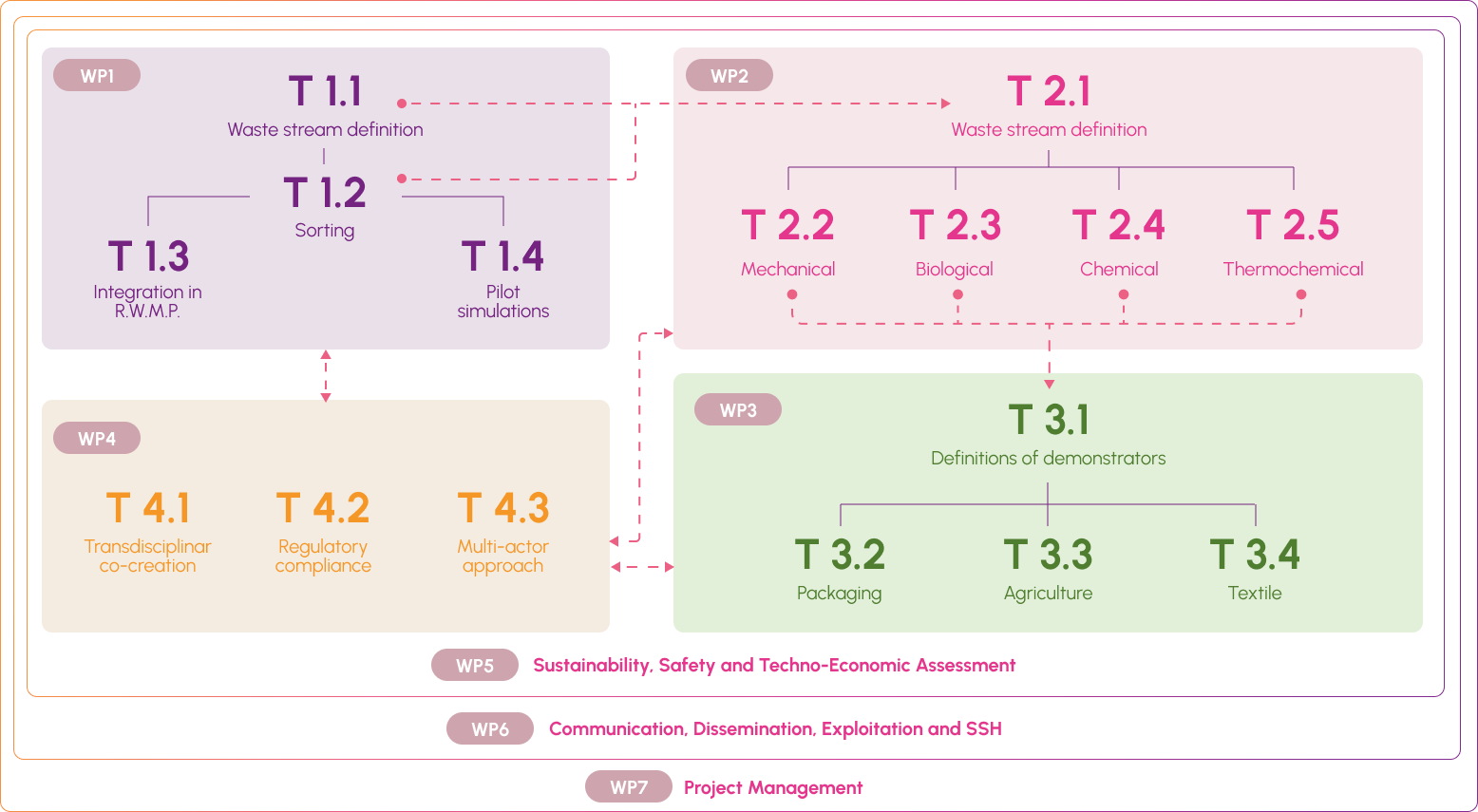

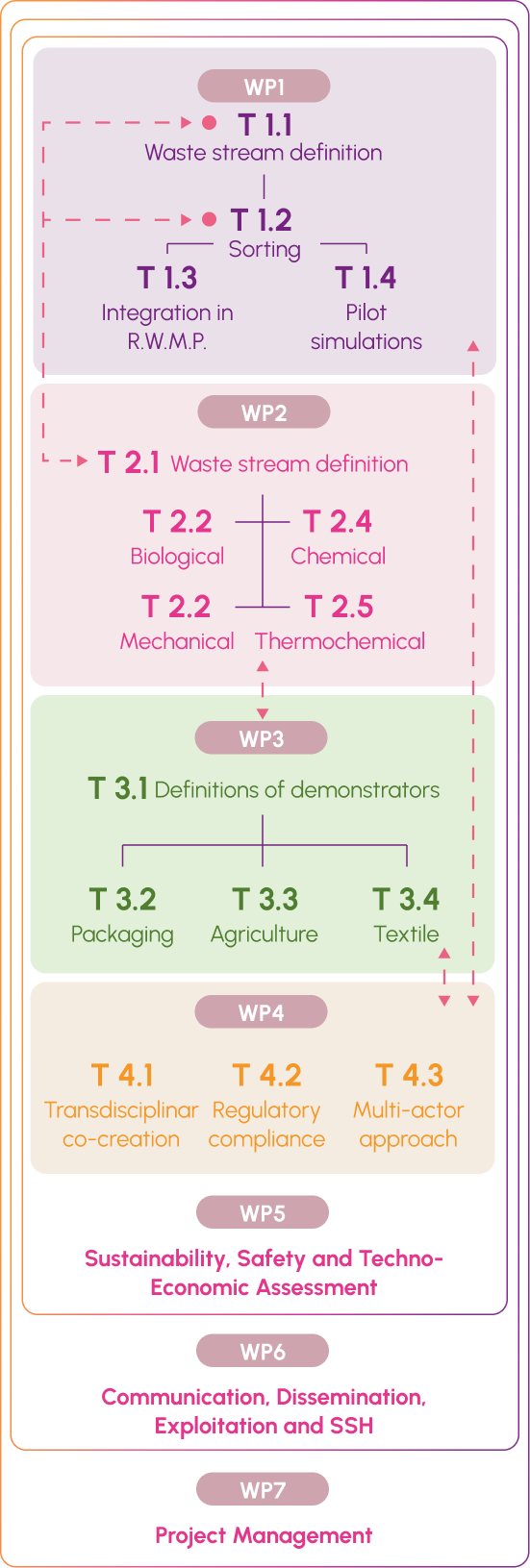

MOEBIOS project will be based on a 48-month Work Plan divided into 7 Work Packages

Work plan and resources

The implementation of the MOEBIOS project will be based on a 48-month Work Plan divided into 8 Work Packages, interrelated, as presented below, ensuring coherence

Turning waste into opportunities

Define and forecast the future presence of biobased polymers in packaging, textile, and agricultural waste streams. Develop and demonstrate enhanced sorting methods for high-performance separation in waste management plants across these sectors.

Task 1.1. Definition and characterization of BPs waste streams

This task focuses on defining and characterizing biobased waste streams in packaging, textile, and agriculture sectors over 42 months. It involves identifying current and future bioplastic presence, typology, and contaminants, while developing scenarios based on regulatory, technical, economic, and social trends. The task includes designing sorting trials and ensuring regulatory compliance. Additionally, primary producers will be engaged through public announcements and questionnaires to assess their roles in the plastics value chain and collection schemes.

Task 1.2. Development of optimized sorting and separation systems

First, the existing database will be updated with bioplastic information using spectroscopy techniques. LEITAT will characterize the sorting process and develop a tracking system to predict object positions on the conveyor. ALIA, NOVIS, ABO, LEI, and PIC will evaluate waste streams to design the arrangement and operation of sorting systems. LEITAT will create a picking algorithm and study various grippers for handling different objects. Finally, PIC will oversee technology evaluation and conduct upscaling studies.

Task 1.3. Sorting simulations of different production scenarios

PIC and LEITAT will validate technologies and algorithms in a real environment, integrating automatic picking systems and grippers into PIC’s sorting systems to assess feasibility for recycling plants. Different scenarios from task 1.1 will be replicated in PIC’s Test Center for various testing trials.

Task 1.4. Implementation/Integration of the developed solutions in the waste management plants

Based on results from T.1.2 and task 2.1 regarding residue pretreatment, engineering studies will be conducted to integrate the developed solutions into real waste management plants for sectors involving ABO, NOVIS, and ALIA. LEITAT will provide PIC with a BP database from NIR HSI technology, and PIC will supply waste managers with necessary equipment specifications. The final engineering report will cover synergies within packaging, agriculture, and textile sectors at both national and European levels, influencing exploitation activities and economic assessments in task 5.4.

Novel technologies for enhancing biobased plastics waste recycling

Optimize recycling methods and implement an enzymatic discovery pipeline for bio-recycling. Scale up techniques to TRL 6/7, ensuring compatibility with real recycling plants.

Task 2.1. Conditioning and pretreatment of the different biobased waste streams

In the packaging and agriculture sector, ITENE will replicate a typical recycling line to demonstrate the recyclability of biobased plastic residues. ITENE will characterize and pretreat these residues, optimizing processes like particle size reduction, washing, and flotation. These processes will be scaled up in ITENE’s pilot line, preparing materials for further steps. TRANSS will then scale up the pretreatment for agriculture and packaging residues to a 2-ton volume per trial. For textile waste, NTT will perform pretreatment steps including washing, drying, and removing impurities, preparing at least 100 kg for subsequent recycling phases.

Task 2.2. Mechanical Recycling

ITENE will analyze preconditioned residues for mechanical, thermal, and rheological properties and optimize the extrusion process using a twin-screw extruder. TRANSS will scale up the extrusion process to validate it on an industrial scale, producing a minimum of 700 kg. IPC will define and test model contaminants in bio-based plastics to optimize decontamination processes. For textile waste, NTT will conduct mechanical recycling to produce staple fibers, characterized for length and morphology. NOV will prepare pre-treated agricultural bioplastic samples, conduct recycling trials, and scale up the process to produce high-quality recycled bioplastic granules for agricultural applications.

Task 2.3. Chemical Recycling

ITENE will adapt chemical recycling processes for sorted fractions, focusing on hydrolysis or alcoholysis of bioplastics like PLA, PHAs, PBS, and PEF. Trials will be conducted at a 3/5 liter scale using acid catalysts under moderate conditions. ITENE will also optimize purification methods with TEC’s support, aiming for high-purity monomers and green solvents. TEC will define and test re-polymerization protocols for treated hydrolysis products. NOV will conduct proprietary chemical recycling trials at a 1-2 kg scale, optimizing depolymerization and re-polymerization processes. Finally, NOV will scale up to TRL7, validating biodegradable bioplastic formulations for agricultural applications.

Task 2.4. Bio-recycling

Different enzymes like cutinases and esterases will be tested by ASA and ITENE for their ability to degrade bioplastic compounds. The most efficient enzymes will be produced using the yeast Pichia pastoris, scaled up from lab scale to 300 liters. The best-performing enzymes will be provided to ITENE, which will develop and optimize the bio-recycling process through controlled enzymatic depolymerization. Up to 1000 liters of bioplastic hydrolysates will be generated for upcycling and validation activities. Downstream processing will include filtering, crystallization, and separation to recover and reuse depolymerization co-products.

Task 2.5. Themochemical Recycling

A preliminary analysis of Non-Recyclable Bioplastic Waste will be conducted, measuring density, granulometry, moisture, fixed carbon, volatiles, ashes, calorific value, and elemental composition. GW2H2 will condition samples for thermochemical processing, testing different granulometries. Thermochemical treatment will be performed in lab-scale and semi-industrial reactors at varying temperatures and residence times, with characterization by GC-MS and FTIR. Gas analysis will determine composition and contaminants, informing the optimal gas cleaning methodology. Finally, a hydrogen separation system will be integrated for continuous pilot operation, certifying the renewable hydrogen quality to achieve TRL 7.

Development of demonstrators based on recycled biobased plastics

Develop environmentally superior end products with enhanced technical properties. Validate in real-world settings to ensure operational requirements and demonstrate scalability of recycling methods.

Task 3.1. Definition of the targeted r-products.

3.1.1, ITENE, SAPA, AUS, and EROSKI will define the requirements for recycled materials in food packaging, focusing on thermal resistance and mechanical properties for ready-meals. SAPA will specify processing needs like sheet width and thickness.

3.1.2, BARBIER and NOV will develop agricultural films with high recycled and biobased content, ensuring mechanical strength and UV resistance.

3.1.3 led by NTT and FIBRO aims to upcycle mechanically recycled textiles into high-value products, including non-woven shopping bags, technical fibers, and apparel, supporting characterization through preliminary spinning trials to assess suitability for melt spinning.

Task 3.2. Upcycling and validation of packaging

ITENE will develop formulations based on recycled biopolymers, such as PHA, PLA, and PEF, blended with other biopolymers and additives to meet Task

3.1 requirements. These formulations will be compounded using a twin-screw extruder, optimized via simulation software, and characterized for thermal and rheological properties to ensure no degradation occurred. Sheets of various thicknesses and layers will be produced through cast coextrusion and processed into prototypes of trays using a thermoforming machine, with parameters optimized to mimic industrial processes. The trays will undergo comprehensive testing for thickness distribution, compression resistance, drop resistance, and barrier properties, followed by sealing compatibility checks and thermal process validations. EROSKI will conduct final product validation through real-world scenario testing, transportation, storage conditions, and shelf-life assessments.

Task 3.3. Upcycling and validation of the agriculture application

NOV will develop formulations based on recycled biodegradable biopolymers for agricultural applications, considering Task 3.1 requirements. Various biopolymers like PHA, PLA, PBS, and PBAT, along with additives, will be compounded using a twin-screw extruder. These formulations will undergo thermal, viscosity, and mechanical characterization to ensure no degradation during recycling and to validate their suitability for agricultural films. The compounds will be processed into films using a blown coextrusion line and tested at lab scale by BARBIER, with adjustments made to maximize recycled and biobased content. Field testing of industrial prototypes will be conducted in collaboration with customers.

Task 3.4. Upcycling and validation of textiles

FIBRO will use recycled polymer to test its suitability for different fiber types, starting with coarse intermediates for air-textured yarns and progressing to finer filaments. All fiber and yarn samples will be used to produce textile demonstrators. NTT will process mechanically recycled textile waste into non-woven shopping bags using air-laid technology, followed by coating to reduce microplastics release. The fibers and final textile products will be characterized according to ISO standards for mechanical properties, creep behavior, and appearance.

Integration of the circular value chains

Develop a trans-disciplinary process to cover the entire value chain from collection to manufacturing. Implement a multi-actor approach to inform policies and ensure compliance with regulations for bioplastic recycling.

Task 4.1. Transdisciplinary co-creation ad co-ownership

As described in sec. 1.2.15, a working group of ~10 stakeholders will be created by EF in collaboration with EUBP and the rest of the consortium, to accompany the design and execution of WP 1 – 3 through the route described in Fig. 8. All the partners on each WP will participate in these workshops. EF will act as intermediate to facilitate the flow of information, moderate the meetings and oversee from the IP-security perspective.

Task 4.2. Regulatory compliance

EF will develop the continuous monitoring of legislative aspects throughout the project to help ensure compliance with legislation contained in sec. 2.2.2.C and any other relevant one, including national-level. All along the project, the outputs from MOEBIOS will be benchmarked against the applicable EU Norms and Regulations. Moreover, microbiological analysis of the streams before valorisation will be evaluated in order to categorize them to the intended uses and to ensure food safety requirements for future uses of the high-quality streams

Task 4.3. Multi-actor approach and Recommendations to Stakeholders

4.3.1: Co-design through MAA Engagement MOEBIOS will organize 4-6 network events over 48 months, collecting stakeholder inputs for WP 1-5 and formulating recommendations. Additional focus sessions will be held to integrate stakeholder feedback into project activities.

4.3.2: Recommendations for Certification and Standardisation EUBP will monitor EU standards and certification schemes, liaise with relevant CEN Technical Committees, and provide recommendations to improve certification processes. Panel discussions will ensure that certifying bodies consider the latest technical achievements.

4.3.3: Recommendations to Policy Stakeholders EUBP will draft and circulate two policy briefings, addressing resource efficiency, waste management, and other relevant topics for policymakers. These briefings will include insights from project results and stakeholder evaluations.

4.3.4: White Paper on Recycling Opportunities A White Paper will summarize project results and advancements in bioplastic recycling. It will address waste managers, policymakers, and investors, providing comprehensive insights into current practices, opportunities, and the circular economy context.

Sustainability, Safety and Techno-Economic Assessment

Validate MoeBIOS technology for industrial development and assess its economic feasibility and environmental impacts. Develop a digital tool to support decision-making by showcasing system performance and social impacts.

Task 5.1. Safety and Sustainability by Design

5.1.1: Safe and Sustainable Criteria

ITENE will guide the design of prototypes according to the EU’s Safe and Sustainable by Design (SSbD) framework. The criteria and assessment methodologies will cover raw materials, products, and processes, following a 5-step methodology:

- Hazard assessment of materials and chemicals.

- Human health and safety during production and processing.

- Health and environmental impacts during final application.

- Environmental sustainability throughout the life cycle.

Social and economic dimensions.

New Approach Methodologies (NAMs)

ITENE will develop and validate New Approach Methodologies for SSbD assessments in agriculture, textiles, and packaging prototypes within the MOEBIOS project. These NAMs will use an iterative approach, focusing on safety and sustainability assessments with cost-effective data generation methods that rely on non-animal testing.

Task 5.2. Safety Assessment

Subtask 5.2.1: Hazard Assessment ITENE will conduct safety assessments of prototypes, starting with raw materials and chemicals, followed by final products. This includes in vitro eco- and toxicological tests, cytotoxicity and genotoxicity tests on human cell lines, and impact tests on aquatic organisms. Migration tests per food contact regulations (EC No. 1935/2004 and EU No. 10/2011) will also be performed, including risk analysis of unintentionally added substances (NIAS).

Subtask 5.2.2: Process Risk Assessment ITENE will assess particle release and emissions during production and recycling, identifying exposure hotspots through various scenarios. Monitoring campaigns in industrial and recycling facilities will be conducted if necessary. Measures to protect workers, such as process compartmentalization, engineering controls, administrative controls, and PPE, will be implemented. Computational simulations and in-situ measurements will be carried out in critical areas. Subtask 5.2.3: REACH Compliance Assessment ITENE will gather product composition information and conduct screening characterizations to ensure the absence of substances of very high concern (SVHC) and restricted substances, complying with REACH regulations. This includes a comprehensive Chemical Safety Assessment (CSA) covering physical, chemical, human health, and environmental hazard assessments, and classification and labeling under CLP.

Task 5.3. MoeBIOS Decision Support System Framework

To assess the economic, environmental, and social impacts of MOEBIOS technology a full data set will be created. Process simulation software such as ASPEN PLUS will be chosen to perform this task. Zer0-E will start with the modelling of MOEBIOS processes to generate a flow diagram. Parameters for the simulation will be taken from technological partners and then integrated to form a complete process. An optimization of the processes will be carried out to obtain the best parameters including energy, resources, operating conditions, and costs, through sensitivity analysis (e.g., in different conditions). The results of the technical evaluation will be further applied to the life cycle sustainability assessment (LCA, LCC, S-LCA) of MOEBIOS technology.

Task 5.4. Economic impact assessment and Technoeconomic assessment (LCC-TEA)

LCC analysis, conducted alongside LCA, assesses the cost of the entire chain for selected technologies through TEA and cost-benefit methodologies. It involves two steps:

- Cost Identification: Determining CAPEX and OPEX, calculating economic indicators like investment cost, ROI, and NPV. LEITAT provides technology cost information for sorting.

- Economic Feasibility Study: Evaluating the positive economic benefits of biotechnology systems. PIC conducts economic analysis for introducing sorting technologies in new machinery.

The analysis will identify overall investment and operating cost reductions and assess the cost-effectiveness of proposed technologies compared to current techniques. Sensitivity and risk analyses will evaluate different scenarios, such as price variations.

Task 5.5. Environmental impact assessment (LCA)

Scope Definition

The evaluation method and strategy for data collection will be defined for each MOEBIOS process, with data inputs from technical partners. Inventory Analysis Energy, resources, and waste flows associated with MOEBIOS processes and products will be determined in collaboration with task partners. Zer0-E will define environmental KPIs, including manufacturing emissions and resource usage.

Impact Assessment

Potential environmental impacts, such as climate change, human toxicity, ecotoxicity, acidification, eutrophication, ozone depletion, and resource consumption, will be evaluated throughout the life cycle of MOEBIOS technology. Interpretation of Results Results will be used to evaluate the final MOEBIOS technology concept for industrial applications. The LCA will utilize software like SigmaPro and follow ISO 14040/14044 guidelines to assess environmental benefits compared to other technologies.

Task 5.6. Social impact assessment (s-LCA)

Social analysis will assess whether MOEBIOS technology can be accepted by customers and end-users, in addition to meeting regulations. This involves a Social Life Cycle Assessment (S-LCA) based on environmental (LCA) and economic (LCC) analyses. S-LCA evaluates the social and socioeconomic aspects of project processes, considering their impacts on stakeholders like workers, local communities, consumers, value chain actors, and society. Aspects include human rights, working conditions, health and safety, and socio-economic repercussions. Zer0 will conduct the S-LCA studies with data from technical partners and discussions with researchers, industry, policymakers, NGOs, and Trade Unions.

Task 5.7. MOEBIOS digital tool development as DSS.

Zer0 will develop a digital DSS. It will display all critical data for each waste stream to be processed: energy consumption, raw materials, feedstocks, etc., depending on the properties of streams: complexity of the mixture, composition, etc. To do so, ZER0 will gather inputs from WP 1 – 3. This DSS will constitute an evidence-based “best-practices” framework for bioplastics recycling to provide waste managers an action line of sustainability management in the field. The digital tool will be developed through the selection of programming languages such as Python or MATLAB for the backend full stack process, and LabVIEW for the frontend process (interface) to integrate both economic, social, and environmental vectors. The technical partners and Zer0 will analyse the prediction model to work with the information from Task 5.1. using AI and ML tools and algorithms.

Communication, Dissemination, Exploitation and SSH

Validate MoeBIOS technology for industrial development and assess its economic feasibility and environmental impacts. Develop a digital tool to support decision-making by showcasing system performance and social impacts.

Task 6.1. Dissemination campaing

All non-confidential information and knowledge from the project will be distributed according to IP protection rules. This includes participation in media outlets, eight sectorial and eight scientific publications, attending scientific conferences, organizing three workshops with industry stakeholders, and two roundtables with EU policymakers. A final event will present project results and exploitation strategies. Dissemination will follow Open Science requirements. Collaboration with other projects will be facilitated through working groups, meetings, and joint dissemination activities to exchange results and create synergies.

Task 6.2. Communication campaing

The MOEBIOS branding campaign will utilize selected channels to educate the public about bioplastics pollution and project benefits through storytelling. Key measures include:

- Project Website (M4): A virtual hub for bio-plastics recycling updates, featuring project advances, infographics, and videoclips. It will also host the MOEBIOS Green Open Access Channel for public articles and reports.

- Social Media and Promotional Campaign: Engaging audiences via LinkedIn, Twitter, and YouTube, with briefings and press releases to mass media contacts. A virtual Info Day will be organized by M12.

- 6-Monthly Newsletters and Press Releases: Updates on project news, streamlined through Horizon Europe and CBE channels.

- Creative Graphics and Printable Materials (M2): Eye-catching visual content and technical materials for dissemination and exploitation activities.

These efforts aim to maximize visibility and engagement with stakeholders and the public.

Task 6.3. Consumer engagement and acceptance

6.3.1: Consumer Engagement Lead: EROSKI; Partners: FIBRO, BARBIER

- Textile and Agriculture Demonstrators: An online survey will be conducted to gather consumer feedback on recycled bio-based prototypes from FIBRO and BARBIER, involving approximately 50 subjects each. The survey will assess user-friendliness (especially for textiles) and technical performance.

6.3.2: Study of Consumer Perception for Packaging Demonstrator and Labelling Scheme Lead: EROSKI; Partners: FIBRO, BARBIER

- Survey Design: A questionnaire will be created to understand consumer perceptions of food packaging made from recycled materials, focusing on conservation properties and environmental safety. This complements the societal assessment (s-LCA) from WP5.

- Survey Distribution: The questionnaire will be distributed to EROSKI consumers, through the Citizen Science Platform, newsletters, consumer magazines, and partner associations of the European Consumers Union (ECU) for EU-wide coverage.

- Consumer Panel: A panel of approximately 100 consumers will be involved to obtain hedonic, sensory, and emotional profiles of the prototypes, investigating congruence with specific food products.

- Focus Groups: Three focus groups, including associations, companies, and institutions, will discuss the findings to align the project with consumer requirements.

- Data Collection: Demographic data, willingness to buy recycled bioplastic products, and attitudes towards sustainability will be collected to identify different consumer segments and evaluate the information’s effect on various groups. This information will be incorporated into the Business Planning study in Task 6.4.

Task 6.4. Assessment of the market uptake potential and exploitation

A PEDR will be established to maximize the impacts of the MOEBIOS project and facilitate the exploitation of all generated knowledge and results. 6.4.1: Market Uptake Potential Assessment

- Business and Exploitation Routes: Mapping potential routes for each recycled product to advance TRLs and reach the market (e.g., direct sales, IP transfer).

- Plan Components: Development status, SWOT analysis, market analysis (PESTEL), market positioning, competitor analysis, customer willingness to pay, financial projections, risk analysis, and feasibility of creating a startup.

- Stakeholder Consultations: Engaging plastic producers, converters, and brand-owners for insights.

6.4.2: Maximizing Replicability in the EU27 Waste Management System

- Replication Strategy: Defining replication, technology transfer, and scaling-up of MOEBIOS technologies into current waste management practices.

- Training Modules: Developing and delivering training to ensure knowledge transfer and post-project sustainability.

- Stakeholder Consultations: Engaging industry representatives, waste managers, recyclers, plastic producers, investors, and environmental agencies for feedback.

- Replicability Plan: Creating a plan to replicate recycling processes, identifying customers and IP licensees, and coordinating with decision-makers for funding applications.

These efforts aim to ensure the continuation and broader impact of the MOEBIOS project after its completion.

Project Management

Manage the consortium to ensure smooth project execution and integrate efforts across all partners. Oversee scientific and technical management within individual work packages (WPs).

Task 7.1. Project Management

The project will be coordinated and monitored to ensure smooth execution, with meticulous oversight of all activities. This includes organizing and documenting General Assembly meetings and supervising managerial roles to adhere to decision-making procedures. Progress will be tracked and reported to the CBE through internal reports from WP leaders. Financial and administrative management will handle the project’s finances and ensure compliance with contractual obligations. Risk management will involve continuously updating risk statuses, devising mitigation strategies, and implementing contingency plans as needed. Finally, the project will culminate in a final assembly, likely held alongside the International Final Workshop. Task 7.1.1: Data Management and Open Science

- Data Hosting and Curation: All project data will be hosted on the project intranet for internal use, including LCA, LCC, and s-LCA results. Open Access results will be available on the project website and platforms like EOSC, OpenAire, and Cordis.

Task 7.1.2: Ethical Issues and Responsible Research

- Oversight of Ethical and Societal Issues: Managing ethical considerations related to research activities, handling data from consumer studies, ensuring regulatory compliance, engaging with policymakers and the public, managing innovation, and protecting IPR.

These tasks ensure effective project management, data transparency, and adherence to ethical standards throughout the project lifecycle.

Task 7.2. Innovation and IPR management

This task ensures systematic knowledge management for IPR, exploitation, and dissemination activities in WP6, incorporating MAA and a trans-disciplinary approach. Led by EF as the Innovation Manager, the task bridges technical results and market demands, identifying business opportunities, customer segments, and value propositions. It involves tracking the TRL evolution for each Key Exploitable Result (KER) to monitor market readiness. Key Components:

- Knowledge and IP Management:Capturing and managing IP generated by the MOEBIOS project. Setting up knowledge management and protection measures. Ensuring safe dissemination and fair exploitation of project results.

- IP Protection and Strategy:Regular screening for novelty, patentability, and protection of results. Implementing appropriate IP protection strategies (patents, copyrights, trademarks). Conducting patent watches to confirm the novelty and freedom to operate (FTO).

- Contractual Mechanisms:Using NDAs or trade secrets to protect business information or know-how. Following a publication clearance procedure to avoid disclosing information before protection. Supporting inventors with IPR rules compliance and additional agreements as necessary.

- Market and Business Focus:Mapping TRL evolution for KERs. Identifying real business opportunities and required value propositions. Ensuring partners’ background knowledge is secured according to the IPR strategy.

Deliverables:

- IP Strategy (D7.3): Includes a policy on publication results and IPR management plans.

- Monitoring and Reporting: Tracking progress and ensuring all protectable results are appropriately protected.

This comprehensive approach aims to derive the greatest commercial value from the project’s intellectual assets, ensuring effective knowledge dissemination and protecting innovations.