A few years ago, bioplastics were widely embraced as a sustainable alternative in packaging sector—Sugarcane-based bottles, compostable bags, and bio-labeled containers filled supermarket shelves with the promise of greener choices. But today, both consumers and experts are raising legitimate concerns. Are bioplastics truly part of the solution, or are we facing another case of well-meaning greenwashing?

At MoeBIOS, we’re not afraid to ask hard questions. As an EU-funded project committed to advancing a circular bioeconomy, we rely on evidence, not trends. This post separates hype from reality and outlines a more honest, science-based path forward.

The science: what bioplastics can—and can’t—do

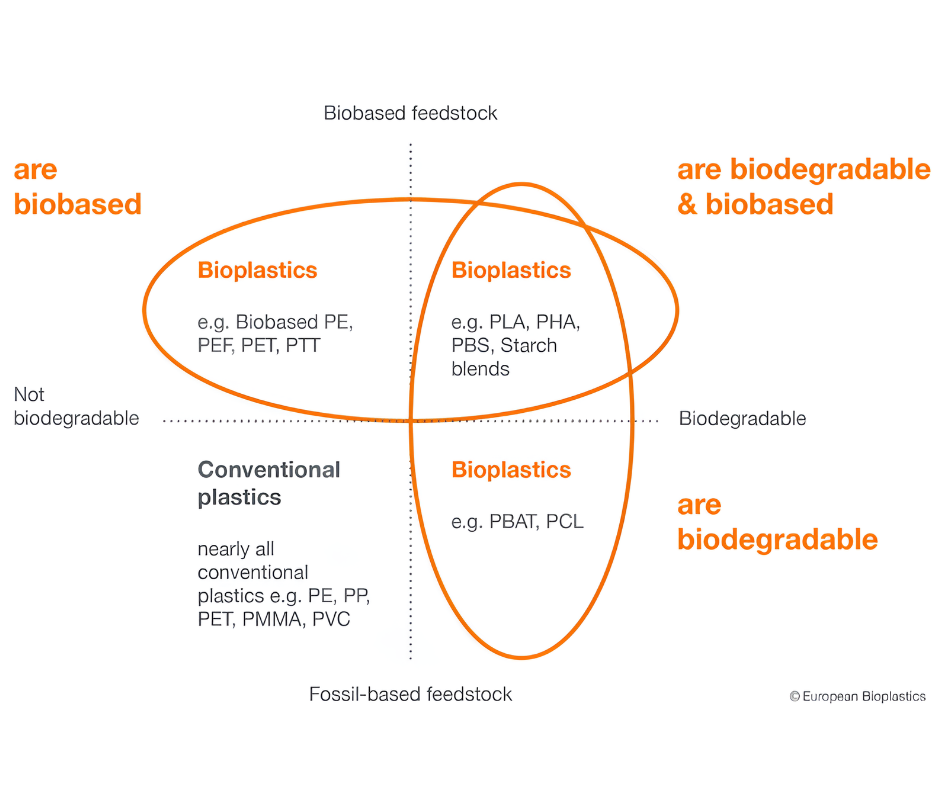

Let’s start with the basics: Bioplastics are not a single category—they vary by feedstock, end-of-life pathways, and environmental impacts:

- Bio-based plastics like bio-PE or PEF are made from renewable sources but behave like fossil plastics unless properly managed.

- Biodegradable plastics break down under specific conditions—but not all biodegradables are compostable.

- Compostable plastics such as PLA need industrial composting to degrade effectively, and even then, they must meet strict certification criteria like EN 13432 or ASTM D6400—which often do not reflect real-world waste systems (European Bioplastics, 2024).

According to a 2024 meta-analysis, some bioplastics can reduce greenhouse gas emissions and fossil energy use. However, when disposed of in landfills, they may release methane, especially if designed for industrial composting (Yadav and Nikalje, 2024).

Feedstock matters: cornfields or ocean farms?

The origin of bioplastics plays a crucial role in their overall sustainability profile. For instance:

- Materials like PLA and bio-PE are often made from food crops like corn or sugarcane, raising concerns about land use, deforestation, and the impact on global food security (Sustainability Directory, 2025).

- A 2024 footprint analysis warns that replacing all fossil-based plastics with bioplastics derived from crops could demand as much as 61% of the world´s arable land and consume around 18% of freshwater resources (Biodegradable Bottles Report, 2024).

At MoeBIOS, we promotes a different approach: Instead of relying on virgin biomass, we focus on recycling and upcycling existing bioplastics waste from packaging, agriculture, and textiles.

Even marine-derived biopolymers, like PHA from algae, show promise. They’re biodegradable in soil and oceans—unlike PLA—but currently face scalability limits (Tennakoon et al., 2023).

Biodegradable vs compostable: Understanding the fine line

The term “biodegradable” and “compostable” are often used interchangeably, but they refer to very different processes—and that can cause confusion. Simply labeling a product as biodegradable does not guarantee it will break down easily in your home compost or natural environment.

A side-by-side comparison:

- PLA (Polylactic acid): Requires industrial composting at 58°C or higher for at least 90 days. If landfilled, it can persist for years and may emit methane.

- PHA (Polyhydroxyalkanoates): Naturally degrades in marine and soil environments, making it highly promising for reducing plastic pollution. However, higher production costs and limited commercial availability currently restrict widespread use.

- PPC-P (Propylene Carbonate and Phthalate Plastics): A relatively new bioplastic with notable recyclability benefits and excellent barrier properties, making it suitable for packaging applications (LX Biotechnology, 2024).

- PBS, PBAT, blends: Combining different bioplastics can tailor properties but also complicate recycling and biodegradation behaviors. PBAT and PBS are biodegradable polyesters often used to improve flexibility and performance in bioplastic blends.

- Most consumers don’t have access to industrial composting—so that “compostable” cup may end up in landfill, or worse, contaminate plastic recycling streams. This lack of waste alignment fuels accusations of greenwashing (GabletopPak, 2024).

The industry view: growing demand, growing pains

The bioplastics sector is experiencing rapid growth. Market projections estimate it will supass 26 billion € by 20230, driven largely by regulatory pressures and shifting consumer expectations (Grand View Research, 2024).

But scale brings complications:

- Production is still small-scale and expensive.

- Supply chains are still unstable and prone to disruption.

- Waste management varies widely between regions (Packaging Gateway, 2024).

Even sustainability major players like Coca-Cola and IKEA face hurdles with cost, performance, and disposal inconsistencies when trying to implement bioplastics at scale (Plastics Technology, 2024).

This is where MoeBIOS comes in—with real-world pilot systems that integrate sorting, recycling, and upcycling of PLA, PBS, PHA, PBAT and their blends. These are designed to work in tandem with existing waste infrastructure, not disrupt it.

Policy is shifting fast

Regulatory frameworks around the world are evolving quickly—and bioplastics are caught in the crosshairs.

In Europe, the Packaging and Packaging Waste Regulation (PPWR) mandates that all packaging be recyclable by 2030. This presents a serious challenge for bioplastics that are not compatible with local recycling or composting systems. Materials that cannot be effectively processed within existing infrastructure may soon fall out of favor, regardless of their bio-bases origins (European Commission, 2025).

Elsewhere, policy momentum is growing but not always aligned with reality. For example, India’s proposed policy would replace half of all single-use plastics with compostables by 2040. However, without matching infrastructure and standards, this could generate more confusion and waste (EY India, 2024).

So… are bioplastics the future?

The honest answer: Yes—but only if we rethink how we design, use, and dispose of them.

They cannot solve the plastic crisis alone. But when embedded into a circular system—where bioplastics are upcycled, recycled, and smartly managed—they offer a powerful tool for sustainable packaging.

At MoeBIOS, we’re not asking whether bioplastics are the future. We’re building the system that makes them fit for it.

Learn more

To follow MoeBIOS’s journey toward sustainable bioplastics recycling:

- Visit our project website

- Follow us on LinkedIn

- Join us on X (formerly Twitter)

Stay informed, stay engaged—and help us redesign the future of sustainable packaging.