Biobased Plastics: A New Chapter in Sustainable Innovation

Today, biobased plastics are not just a green alternative — they represent a revolution. Born from renewable sources like corn starch, sugarcane, or even algae, these materials are designed to reduce our reliance on petroleum-based plastics. But there’s a twist: when combined with artificial intelligence (AI) and nanotechnology, their potential multiplies.

At MoeBIOS, a pioneering initiative in the recycling of bioplastics, this synergy is already a reality. By integrating these advanced technologies, MoeBIOS is leading the charge toward a smarter, cleaner, and more circular materials economy.

The Role of AI and Nanotechnology in Recycling

Both AI and nanotechnology are transforming how we design, optimize, and recycle materials. AI is revolutionizing material science by predicting outcomes, optimizing processes, and minimizing waste — a true efficiency booster. Meanwhile, nanotechnology upgrades the molecular structure of bioplastics to enhance strength, flexibility, and barrier properties.

In short, AI streamlines, and nanotech strengthens. Together, they allow bioplastics to go places they never could before — from smart packaging to biomedical devices.

Benefits of Bioplastics Over Petroleum-Based Plastics

Why make the switch? Biobased plastics offer numerous advantages compared to traditional options. They present a significantly lower carbon footprint, as their plant sources absorb CO₂ during growth, effectively offsetting emissions. The renewability factor cannot be overlooked: unlike fossil fuels, bioplastic feedstocks are regenerative resources. Many varieties also offer biodegradable options that break down in natural environments, reducing persistent pollution. Additionally, these materials tend to be safer for both human health and ecosystems, with reduced toxicity and fewer microplastics.

These benefits align with the European Bioplastics Association’s vision for a sustainable future.

Challenges in Traditional Bioplastics

Despite their promise, early-generation bioplastics had hurdles. They often exhibited limited strength, low barrier performance against moisture and oxygen, and prohibitively high production costs. The inconsistent degradation rates also posed problems for waste management systems. These limitations significantly restricted their application in high-performance contexts — until recent technological breakthroughs changed the landscape.

How AI Accelerates Biobased Plastic Design

Thanks to AI, scientists can now predict polymer structures based on desired properties and simulate material behavior before physical production. This technological advancement dramatically reduces research and development time while avoiding costly trial-and-error approaches through sophisticated machine learning models. AI effectively transforms material development into a data-driven science, simultaneously accelerating innovation cycles and reducing development costs.

Machine Learning for Smarter Recycling

In recycling operations, AI demonstrates remarkable capabilities by sorting plastics through advanced image recognition, predicting contamination levels in waste streams, optimizing logistics for collection and processing, and reducing manual labor and associated errors.

Incorporating AI into sorting systems has substantially boosted recovery rates and ensures consistently cleaner, higher-quality bioplastics.

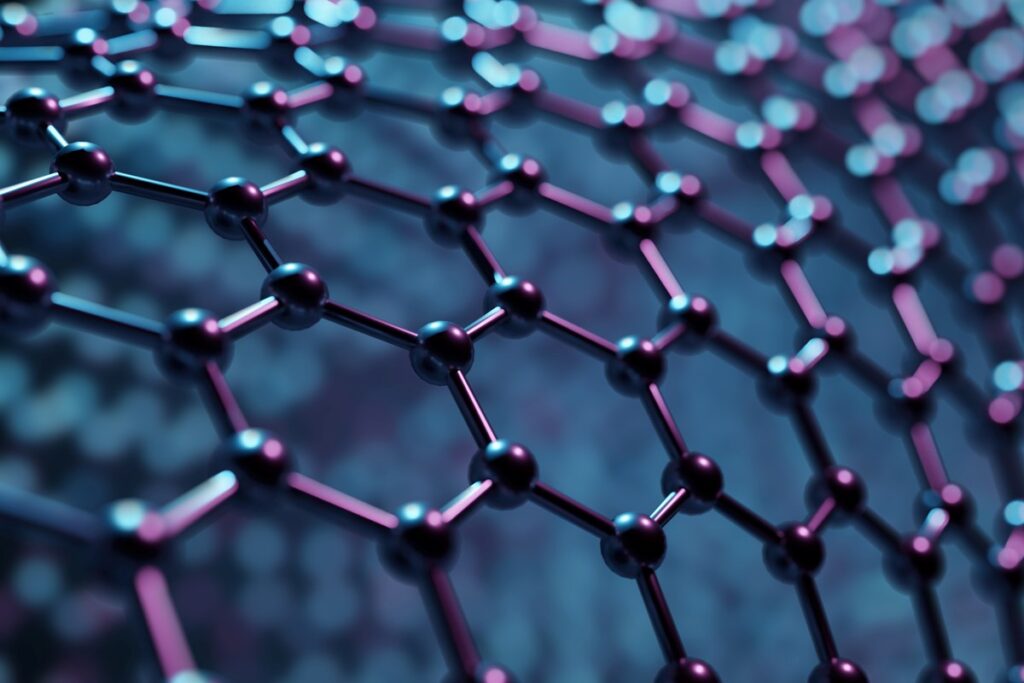

Nanotechnology: A Catalyst for Stronger Bioplastics

Enter nanotechnology — the sophisticated art of manipulating matter at the atomic level. By strategically embedding nanoparticles in polymers, scientists create bionanocomposites with remarkably enhanced properties. These advanced materials significantly improve mechanical resistance through reinforced molecular structures, providing the strength and durability previously lacking in conventional bioplastics. The improved thermal stability enables application in higher-temperature environments, expanding their utility in automotive components and food packaging requiring heat resistance. Equally important are the enhanced barrier properties against moisture and gases, critical for extending shelf life and maintaining product integrity in packaging applications.

Furthermore, these composites can be engineered with specialized functionalities such as antimicrobial protection using silver nanoparticles or UV resistance through zinc oxide integration. What makes this technology truly revolutionary is that these substantial performance enhancements are achieved without compromising the essential biodegradability that defines these materials’ environmental advantage. This balance of improved performance with maintained sustainability represents a pivotal advancement in materials science, positioning bioplastics as increasingly viable alternatives to conventional petroleum-based polymers across diverse industrial applications.

Developments and Examples

Developments in this field showcase promising materials and applications. Cellulose Nanocrystals (CNC) and Nanofibrils (CNF), derived from abundant and renewable sources like wood and agricultural waste, exhibit excellent mechanical properties and are being used to reinforce various bioplastics, including PLA and starch-based polymers. These reinforced materials find applications in packaging, automotive parts, and even biomedical fields.

Chitin and chitosan nanoparticles, derived from crustacean shells and fungal cell walls, offer biodegradability, biocompatibility, and antimicrobial properties. They are being explored for food packaging films with enhanced barrier and antimicrobial functions, as well as in biomedical applications like tissue engineering. Their natural origin aligns perfectly with the sustainability goals of bioplastic development.

Nanoclays such as montmorillonite and kaolinite improve the mechanical strength, barrier properties, and thermal stability of bioplastics at relatively low loading levels. These cost-effective materials have been widely studied for various packaging applications and represent some of the most commercially viable nano-additives for bioplastics currently available.

Research is increasingly focusing on bioactive bionanocomposites that incorporate nanoparticles loaded with bioactive substances such as antimicrobial agents or antioxidants within bioplastic matrices. These advanced materials enable controlled release packaging, further extending shelf life and enhancing food safety through active mechanisms rather than merely passive barrier functions.

Read more about nanotechnology and bioplastics

AI-Driven Bioplastics: Methodologies and Sector Applications

In 2025, advanced AI models enabled the creation of textile-grade biodegradable polymers. By inputting required properties, AI predicted viable polymer structures—a process that would otherwise take years.

Their success showcases how AI isn’t just theoretical—it’s operational.

This approach highlights how biodegradable materials can adapt responsively to environmental factors while maintaining optimal product performance.

Bioplastics in the Packaging Industry

Packaging is the largest application of bioplastics.

Bioplastics are used for an increasing variety of applications, ranging from packaging and fibres to consumer goods, automotive, and agricultural products. Packaging remains the largest market segment for bioplastics with 45 percent (1.12 million tonnes) of the total bioplastics market […]

Fuente: European Bioplastics

With nanotech and AI, materials now offer:

- Moisture and gas resistance

- Antimicrobial surfaces

- Transparency and flexibility

- Faster composting

Smart packaging can even include biosensors that monitor freshness — a plus for food safety.

Applications in Agriculture and Food

In agricultural contexts, bioplastics serve as versatile tools for growth. Biodegradable mulch films reduce soil contamination while simplifying post-harvest cleanup. Controlled-release films for fertilizers and pesticides optimize resource usage. Edible coatings on produce extend shelf life naturally. Through AI integration, release timing and environmental behavior are precisely optimized for specific growing conditions and crop requirements.

Smart Bioplastics for Medical Use

Within healthcare, bioplastics enhanced with nanotechnology have transformed treatment approaches. They’re increasingly utilized in sophisticated drug delivery systems, engineered for tissue regeneration applications, and developed as safe temporary implants that dissolve after serving their purpose. MoeBios plays a crucial role in connecting medical innovators with these green material alternatives, facilitating advances in sustainable healthcare.

Automotive and Electronics Sectors

Industries traditionally dominated by rigid polymers are now exploring bioplastic alternatives. Lightweight, durable biocomposites offer structural integrity with reduced weight. Electrically conductive films incorporating graphene enable new electronic applications. Thermally stable components suitable for under-the-hood automotive applications demonstrate how sustainability meets performance in previously challenging contexts.

Environmental Impact of Nano-Bioplastics

Being biodegradable doesn’t automatically guarantee environmental safety. Consequently, researchers conduct rigorous testing of nanoparticle toxicity on soil and aquatic ecosystems, evaluate degradation rates in various environments including compost and marine settings, and carefully monitor nanoparticle release during use and recycling processes. This responsible design approach ensures comprehensive eco-safety through the material’s entire lifecycle.

Safety and Ethics in Nanotechnology Use

Several essential considerations guide responsible nanotechnology development. These include transparency in product labeling, securing appropriate regulatory approval for nanomaterials, comprehensive public education regarding safe usage practices, and ethical sourcing of raw materials. MoeBIOS actively supports regulatory alignment with established EU safety frameworks to maintain the highest standards of responsibility.

Open Innovation at MoeBIOS

Through its open-access research platform on Zenodo, MoeBIOS shares

- Technical papers

- Infographics and videos

- Project milestones and results

This democratizes sustainability knowledge.

Regulatory Landscape for Bioplastics in Europe

The EU supports bioplastics through:

- The Circular Economy Action Plan

The European Commission’s Circular Economy Action Plan includes a framework for bio-based, biodegradable, and compostable plastics. It aims to reduce consumption by making products more renewable, reusable, and recyclable. The plan seeks to replace fossil-based materials with responsibly sourced, renewable, and bio-based alternatives.

- European Bioplastics Roadmap

Plastics Europe has developed a roadmap for plastics in Europe to be circular and have net-zero emissions by 2050. This roadmap includes milestones for 2030, key actions, and indicators. It projects a gradual substitution of fossil-based plastics, potentially reaching 25% in 2030 and 65% by 2050.

- Funding via Horizon Europe

The EU’s Horizon Europe program funds research and innovation projects on bio-based materials and bioplastics. Between 2014 and the present, over 5.7 billion euros have been allocated to these projects through Horizon 2020, Horizon Europe, and partnerships like the Bio-Based Industries Joint-Undertaking (BBI JU) and the Circular Bio-based Europe.

- Legal recognition of compostable plastics

The EU’s policy framework promotes the use of biodegradable and compostable plastics as a more sustainable alternative to fossil-based plastics. The Packaging and Packaging Waste Regulation (PPWR), adopted in December 2024, sets a deadline for specific items like single-serve coffee pods with paper filters and fruit/vegetable stickers to be industrially compostable.

Taken from Itene

A promising legal horizon lies ahead.

Designing the Next Generation of Plastics

Using AI, developers can now co-design materials with specific performance features, run sophisticated simulations to test degradability under various conditions, and optimize properties for multi-use products that maintain performance through multiple life cycles. This represents a revolutionary approach to performance by design rather than through excessive material consumption.

Nanotech and Bioplastics: Future Synergies

In the near future, we may witness extraordinary innovations emerge. Self-healing plastics could extend product lifespans dramatically. Biosensing implants might revolutionize personalized medicine. Smart compostable electronics could transform how we think about technology lifecycles. This rapidly evolving sustainable technology landscape presents opportunities that MoeBIOS is prepared to explore and develop.

Life Cycle Analysis (LCA) tools empower MoeBIOS and similar organizations to track cradle-to-grave emissions with unprecedented accuracy, measure recyclability potential across various systems, and model ecological impact in real time. This comprehensive approach recognizes that sustainability extends beyond creating green products to implementing green processes throughout the entire product lifecycle.

Examples of Biobased Plastics Materials

Several materials have emerged as current leaders in the bioplastics sector. PLA derived from sugarcane or corn offers versatility across applications. PHA produced from bacteria-fed waste provides excellent biodegradability. TPS made from starch presents a cost-effective solution for many products. Bio-PE and Bio-PET represent renewable alternatives to conventional plastics, though they’re not always biodegradable in all environments.

Tips to Start Your Bioplastic Project

- Use AI to prototype and forecast results

- Start small with nanotech trials

- Focus on renewable feedstocks

- Collaborate with MoeBIOS or similar innovation hubs

Conclusion: A Green Tech Revolution in Biobased Plastics

The fusion of biobased plastics with AI and nanotechnology marks a turning point in materials science. It brings us closer to a future where every product is smart, sustainable, and circular. MoeBIOS stands at the forefront of this transformation, inviting innovators, researchers, and businesses to join the movement.

Want to be part of the change? Explore MoeBIOS, download open resources, and start designing the future — responsibly.